FROM EARTH AND UP

Photographed in April of 2024

Stoneware and Indigo dye

61 x 19 x 4 (cm)

Gui Zhou, China)

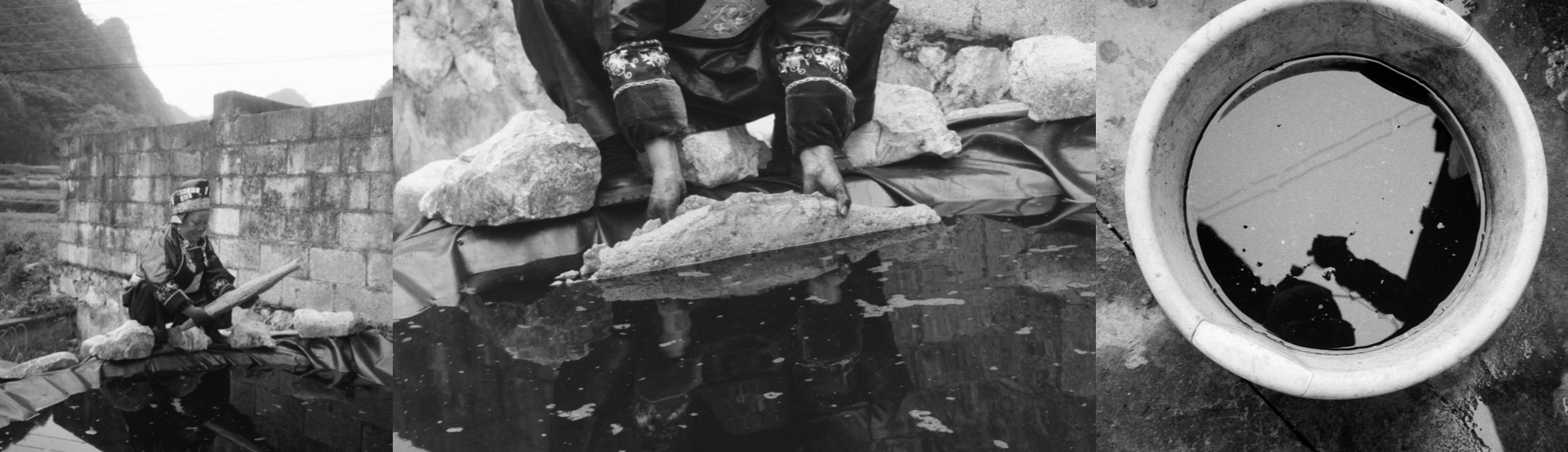

I brought a hand-built ceramic piece to Guizhou to create this documentation and process-based project that investigates the culture and ritual of the traditional Gui Zhou craft of indigo dye.

Like fabric, the ceramic piece is dipped again and again into the cement vat filled with indigo dye at 独山 (Du Shan, Gui Zhou, China). Over time, the indigo, which was once planted and harvested, soaks into the skin and pores of the hand and clay. Inspired by the shape of a boat, the ceramic piece is hand-built from a grog-based clay (the same material as the saggers that were once used to protect porcelain pieces during the wood firing process).

Indigo dyeing in Guizhou follows a centuries-old traditional process, beginning with the cultivation of Indigofera tinctoria, the indigo plant. Farmers plant seeds in spring and tend to the crops through summer, ensuring healthy growth. By late summer, the indigo plants are harvested when they reach full maturity. The leaves are then carefully picked and fermented to produce indigo paste, known as jinsuo. Next, the paste undergoes a fermentation process in large cement vats, where it is mixed with lime and water, creating a rich, dark pigment. For dyeing, textiles—typically hemp or cotton—are soaked in the indigo vat and repeatedly dipped to build up color, allowing the fabric to oxidize in the air between dips. After sufficient layers of dye are applied, the fabric is left to dry. This method, is passed down through generations and is still practiced today. It is used to dye everyday clothes including wedding garments.